Henan Hengyu Electric Group Co., Ltd.

10kV, SBH series oil-immersed amorphous alloy distribution transformers

Classification:

Key Words:

10kV, 20kV, SBH series oil-immersed amorphous alloy distribution

quality 1500 kva oil filled transformer

quality oil-immersed amorphous alloy distribution transformers

Mailbox:

Product Model Meaning

model number | S | B | H | □ | - | M | □ | / | □ |

number meaning | three-phase (physics) | Copper Foil Low Voltage Coils | Amorphous alloy core | Performance Level Designator |

| fully sealed | Rated Capacity |

| Voltage Class |

Product Overview

Amorphous alloy is a new type of energy-saving materials, amorphous alloy processed using rapid rapid cold solidification production process, the physical state of the metal atoms in a disordered amorphous arrangement, which is completely different from the crystalline structure of silicon steel, more conducive to be magnetized and demagnetized, this new type of material used in transformer cores, can significantly reduce the no-load loss of the iron core, known as the new century of " green materials", amorphous alloy transformers are widely used in rural towns, urban residents living in electricity, is one of the important equipment to achieve energy saving and emission reduction in transmission and distribution networks. Green material", amorphous alloy transformer is widely used in rural townships, urban residents living with electricity, is to realize the transmission and distribution network energy saving and emission reduction of one of the important equipment.

Product Features

1. Small no-load current, less heat generation, low temperature rise, stable operation performance.

2. Amorphous alloy core with high saturation magnetic induction strength, not easy to oversaturation, has a better harmonic resistance, effectively improve the quality of power supply

3. Low no-load loss, energy efficient

4. Fast payback

5. Amorphous alloy oil-immersed transformers can reduce the emission of harmful gases such as CO, SO, NO, etc.

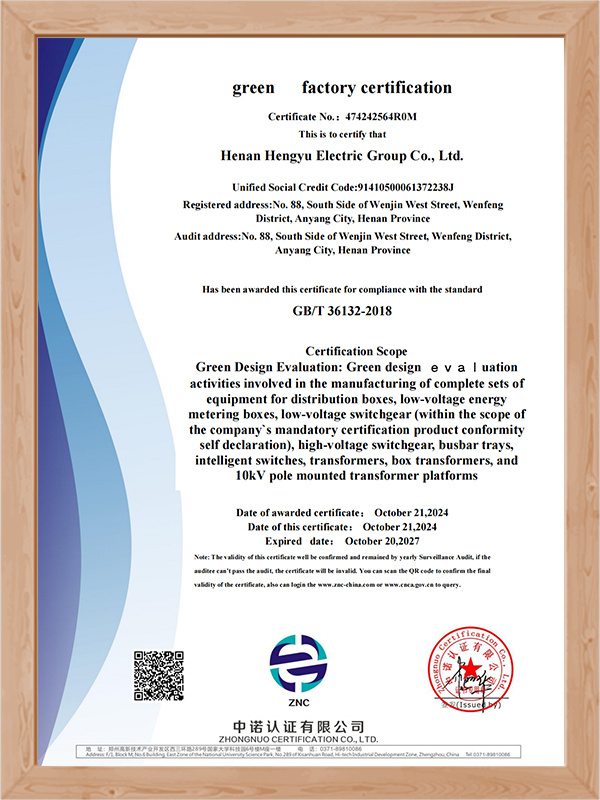

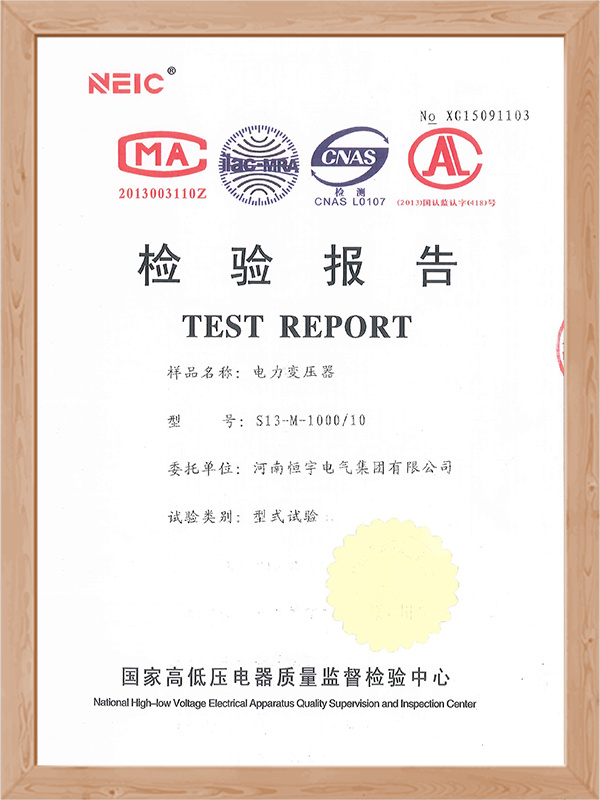

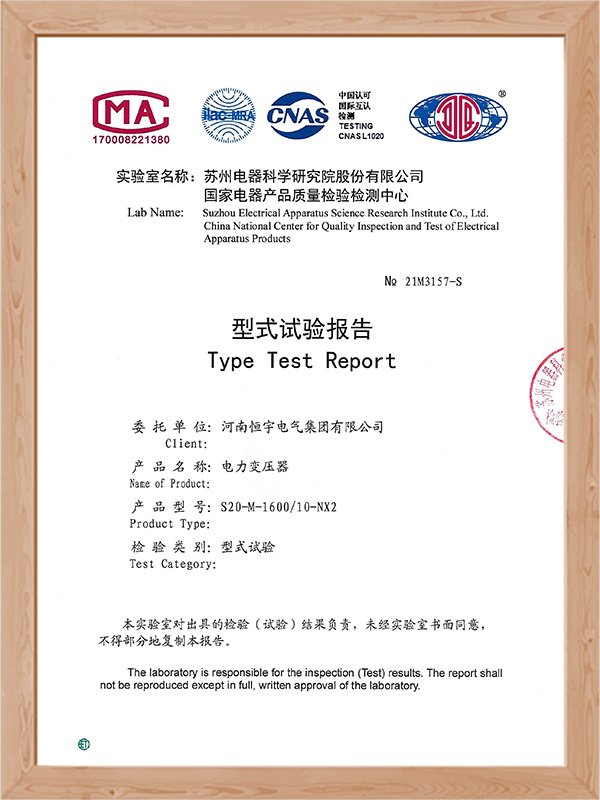

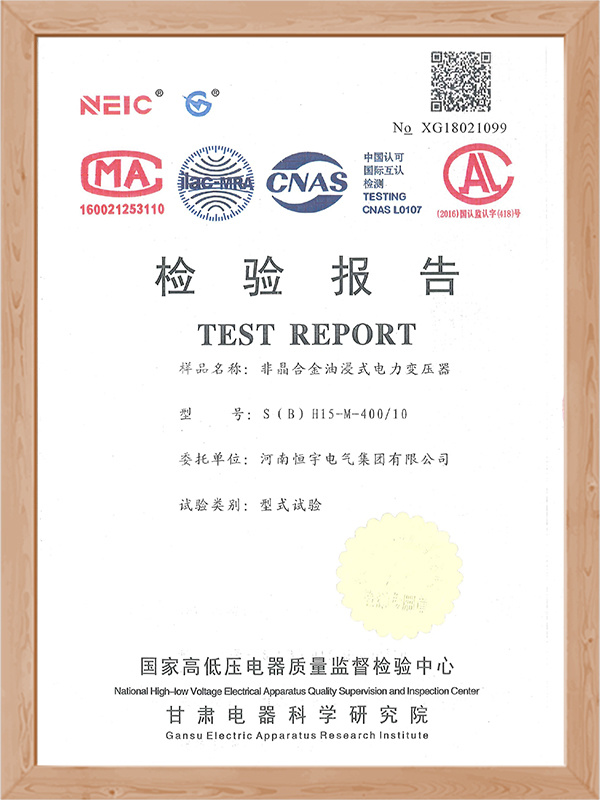

Product Certificate

Transformer Workshop

The Oil-Immersed Amorphous Alloy Distribution Transformer represents a significant advancement in energy-efficient power distribution technology. This transformer is engineered with a core fabricated from amorphous alloy, a metallic glass material that exhibits extremely low hysteresis and eddy current losses compared to traditional silicon steel. The core is hermetically sealed within a robust tank filled with high-grade dielectric oil, which serves the dual purpose of providing superior insulation and dissipating heat generated during operation. This fundamental design makes the Oil-Immersed Amorphous Alloy Distribution Transformer exceptionally effective at minimizing no-load losses, which constitute a major portion of energy waste in electrical networks.

The primary application of the Oil-Immersed Amorphous Alloy Distribution Transformer is to reliably step down medium voltage to lower utilization voltages for end-user distribution in urban, industrial, and commercial power grids. Its exceptional no-load performance ensures substantial energy savings and reduced carbon emissions over the transformer's entire lifecycle, offering a rapid return on investment. The durable construction ensures long-term stability and a low noise level, while the sealed tank protects the core and windings from environmental contaminants and moisture. With its high resistance to short circuits and minimal maintenance requirements, this reliable Oil-Immersed Amorphous Alloy Distribution Transformer is an ideal, future-proof solution for utility companies and large facilities seeking to enhance grid efficiency, reduce operating costs, and support global sustainability initiatives.

| Rated Capacity (kVA) |

SBH25 Series | SBH21 Series | SBH15 Series | |||||||||

|

No-load loss (W) |

Load Loss (W) Dyn11/YynO |

impedance voltage (%) |

No-load current (%) |

No-load loss (W) |

Load Loss (W) Dyn11Yyn0 |

Impedance Voltage (%) |

No-load current (%) |

No-load loss (W) |

Load Loss (W) Dyn11/Myn0 |

Impedance Voltage (%) |

No-load current (%) |

|

| 30 | 25 | 510/480 | 4.0 | 1.3 | 33 | 535/510 | 4.0 | 1.4 | 33 | 630/600 | 4.0 | 1.5 |

| 50 | 35 | 735/700 | 1.0 | 43 | 780/745 | 1.1 | 43 | 910/870 | 1.2 | |||

| 63 | 40 | 880/840 | 0.9 | 50 | 930/890 | 1.0 | 50 | 1090/1040 | 1.1 | |||

| 80 | 50 | 1060/1010 | 0.8 | 60 | 1120/1070 | 0.9 | 60 | 1310/1250 | 1.0 | |||

| 100 | 60 | 1270/1215 | 0.7 | 75 | 1350/1285 | 0.8 | 75 | 1580/1500 | 0.9 | |||

| 125 | 70 | 1530/1450 | 0.6 | 85 | 1615/1540 | 0.7 | 85 | 1890/1800 | 0.8 | |||

| 160 | 80 | 1870/1780 | 0.4 | 100 | 1975/1880 | 0.5 | 100 | 2310/2200 | 0.6 | |||

| 200 | 95 | 2210/2100 | 0.4 | 120 | 2330/2225 | 0.5 | 120 | 2730/2600 | 0.6 | |||

| 250 | 110 | 2590/2470 | 0.4 | 140 | 2735/2610 | 0.5 | 140 | 3200/3050 | 0.6 | |||

| 315 | 135 | 3100/2950 | 0.3 | 170 | 3275/3120 | 0.4 | 170 | 3830/3650 | 0.5 | |||

| 400 | 160 | 3660/3480 | 0.3 | 200 | 3865/3675 | 0.4 | 200 | 4520/4300 | 0.5 | |||

| 500 | 190 | 4380/4170 | 0.3 | 240 | 4625/4400 | 0.4 | 240 | 5410/5150 | 0.5 | |||

| 630 | 250 | 5020 | 4.5 | 0.15 | 320 | 5300 | 4.5 | 0.2 | 320 | 6200 | 4.5 | 0.3 |

| 800 | 300 | 6075 | 0.15 | 380 | 6415 | 0.2 | 380 | 7500 | 0.3 | |||

| 1000 | 360 | 8340 | 0.15 | 450 | 8800 | 0.2 | 450 | 10300 | 0.3 | |||

| 1250 | 425 | 9720 | 0.1 | 530 | 10260 | 0.15 | 530 | 12000 | 0.2 | |||

| 1600 | 500 | 11745 | 0.1 | 630 | 12400 | 0.15 | 630 | 14500 | 0.2 | |||

| 2000 | 550 | 14,000 | 5.0 | 0.1 | 710 | 14800 | 5.0 | 0.15 | 720 | 18300 | 5.0 | 0.2 |

| 2500 | 670 | 15450 | 0.1 | 860 | 16300 | 0.15 | 865 | 21200 | 0.2 | |||

Recommend Products

Consult

We will offer custom quotes and powerful solutions to meet your needs. Send us your details and we'll get back to you as soon as possible.