Henan Hengyu Electric Group Co., Ltd.

35kV, S series oil-immersed distribution transformers

Classification:

Key Words:

35kV, S series oil-immersed distribution transformers

quality 1500 kva oil filled transformer

Mailbox:

Product Model Meaning

| model number | S | □ | □ | □ | - | □ | / | □ |

| hidden meaning | three-phase (physics) | "F" for air-cooled, no code for self-cooled. | "Z" for on-load voltage regulation | Performance Level Designator | Rated capacity (kVA) | Voltage Class (kV) |

Product Overview

This series of products are more advanced in design, and have been substantially improved and enhanced in material, structure and process. The high and low voltage clamping parts are tightened by steel tension band or upper and side beams to form a solid frame structure, which enhances the core clamping force and the ability to withstand transportation impact. Strong short-circuit resistance, beautiful appearance selection, reliable operation, low loss and low noise. As the substation equipment in the field of power transmission and distribution, infrastructure field, public transportation, building and housing, industrial field, information technology field and new energy field.

Conditions Of Use

1. Altitude: ≤1000M;

2. Ambient temperature: -40℃~+40℃;

3. Outdoor wind speed: ≤45m/s

4. Ground inclination: ≤3°.

5. Seismic capacity: horizontal acceleration ≤ 0.3m/s2, vertical acceleration ≤ 0.15m/s2

6. Installation location: no fire, explosion hazard, serious dirt, chemical corrosion and severe vibration;

7. The above conditions of use can not meet the requirements, the user can negotiate with the company to solve the problem.

Product Advantages

1. Iron core (of the heart)

Adopting 45° full diagonal ladder joint technology, effectively reducing no-load loss, no-load current and core noise; using clamps and pulling plate structure to make the core stable and firm as a whole, thus improving short-circuit and impact resistance.

2. Transformers

Cylindrical type for high voltage and cylindrical or foil type for low voltage are adopted to improve the short circuit resistance; the oil guiding structure inside the winding is used to improve the oil flow path, thus reducing the temperature rise and improving the load capacity.

3 Fuel tanks

It is a fully sealed bell-type structure, and the tank reinforcing iron adopts corrugated folded plate structure with fewer welding seams and high mechanical strength; the cooling device adopts chip radiator, which has faster circulating speed, high heat dissipation efficiency, and improves the overload capacity.

4 Body

All insulating parts and welding parts of winding head and lead wire are rounded; steel positioning is adopted on both top and bottom of the body to ensure that the body will not be shifted under all kinds of transportation conditions.

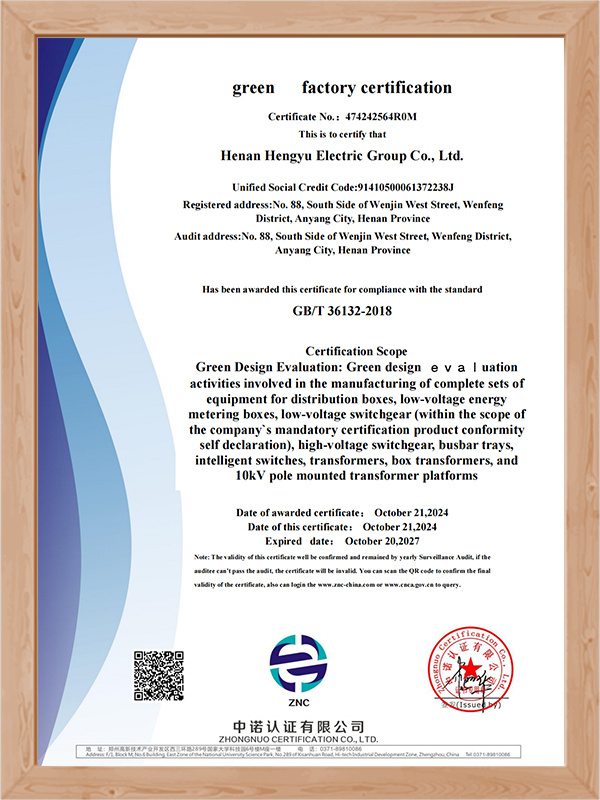

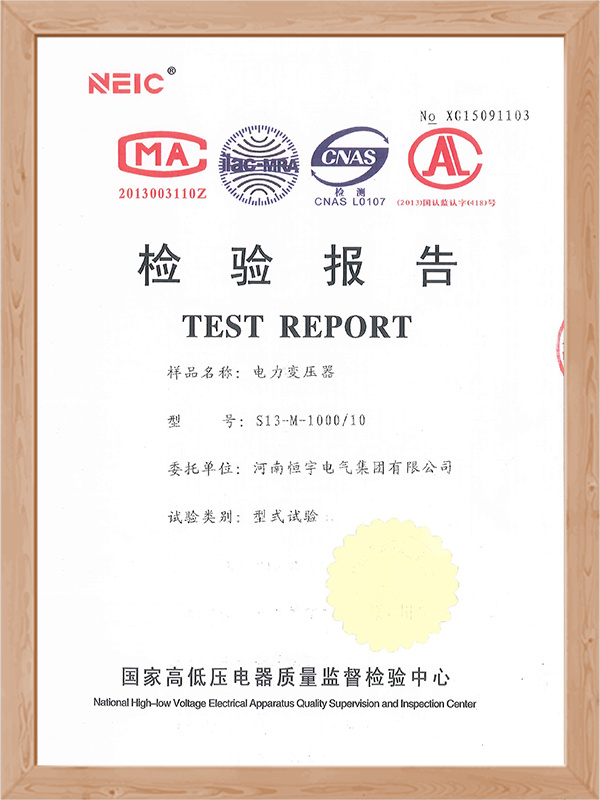

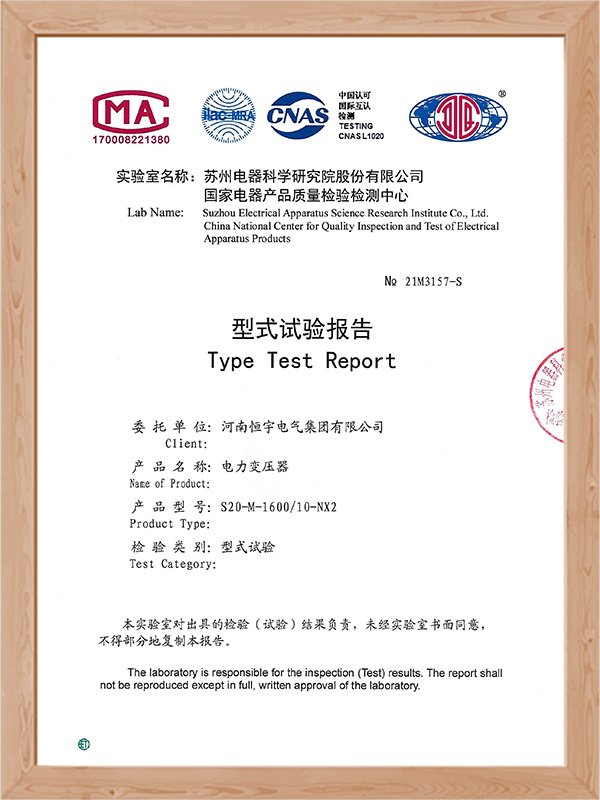

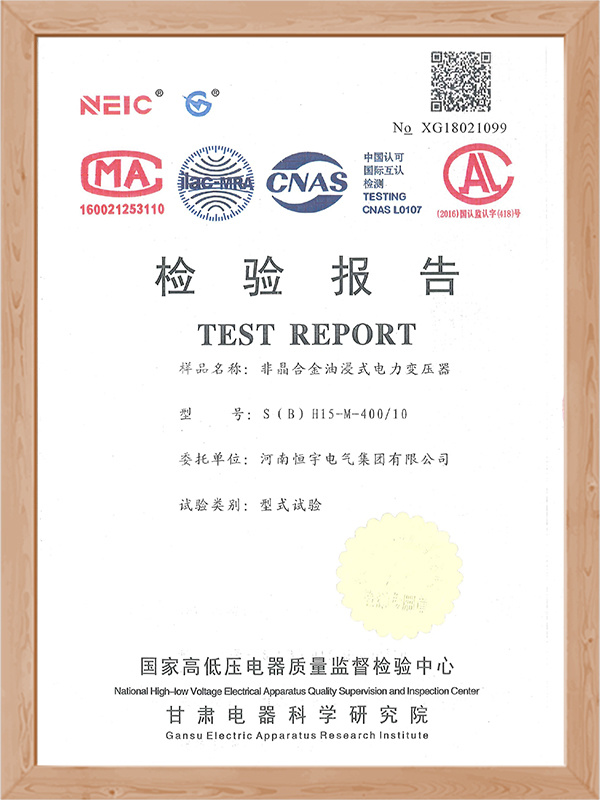

Product Certificate

Transformer Workshop

The 1500 kVA Oil Filled Transformer is a high-performance, three-phase power transformer engineered for superior reliability and efficiency in demanding electrical distribution networks. This product represents an advanced design, incorporating substantial improvements in materials, structure, and manufacturing processes. It is engineered to be a core component within substations, serving critical infrastructure across the public transportation, building and housing, industrial, information technology, and renewable energy fields. The robust construction of this 1500 kVA Oil Filled Transformer ensures strong short-circuit resistance, reliable operation, low loss, and low noise levels, making it an ideal choice for continuous and heavy-duty applications.

This transformer is built to withstand challenging operational conditions. It is designed for altitudes up to 1000 meters, ambient temperatures from -40°C to +40°C, and can endure high wind speeds and seismic activity, making it suitable for diverse outdoor installations. The key advantages of this 1500 kVA Oil Filled Transformer are rooted in its meticulous internal engineering. The iron core utilizes a 45° full diagonal step-lap joint technology, which effectively minimizes no-load loss, no-load current, and core noise. The windings are constructed in a cylindrical or foil-type configuration, enhancing short-circuit resistance, while an internal oil-guiding structure improves cooling and reduces temperature rise. The tank is a fully sealed, bell-shaped structure with a corrugated steel panel design, providing high mechanical strength with fewer welds. This, combined with efficient chip radiators, ensures optimal heat dissipation and improves overall overload capacity. The entire active part is securely positioned to prevent any displacement during transportation, guaranteeing long-term structural integrity and performance.

| 35KV oil-immersed distribution transformer performance parameters | ||||||||||||||||

|

Rated high voltage: 35(33,38.5)KV Rated low voltage: 0.4(0.415,0.433)KV |

Linkage group: D,yn11 or Y,ynO High pressure range: ±2x2.5% |

Rated frequency: 50Hz/60Hz Insulation level: LI200 AC85/AC5 |

||||||||||||||

| rated Capacity (kVA) |

Short Circuit Impedance (%) |

S20 | S13/S18 | S11 |

No-load current (%) |

sound pressure level (A) |

weights (Kg) |

Overall Dimension(cm) | ||||||||

| No-load loss (W) |

Load Loss (W) |

No-load loss (W) |

Load Loss (W) |

No-load loss (W) |

Load Loss (W) |

elder | surname Kuan | your (honorific) | ||||||||

| Dyn11 | YynO | Dyn11 | YynO | Dyn11 | YynO | |||||||||||

| 50 | 6.5 | 120 | 960 | 910 | 130 | 1200 | 1140 | 160 | 1200 | 1140 | 1.3 | 52 | 690 | 1140 | 960 | 1490 |

| 100 | 165 | 1610 | 1530 | 185 | 2010 | 1910 | 230 | 2010 | 1910 | 1.1 | 55 | 900 | 1140 | 1000 | 1600 | |

| 125 | 185 | 1890 | 1810 | 210 | 2370 | 2260 | 270 | 2370 | 2260 | 1.1 | 55 | 990 | 1150 | 1100 | 1650 | |

| 160 | 200 | 2260 | 2145 | 225 | 2820 | 2680 | 280 | 2820 | 2680 | 1.0 | 58 | 1180 | 1150 | 1100 | 1650 | |

| 200 | 240 | 2660 | 2530 | 270 | 3320 | 3160 | 340 | 3320 | 3160 | 1.0 | 58 | 1310 | 1150 | 1150 | 1650 | |

| 250 | 290 | 3160 | 3010 | 320 | 3950 | 3760 | 400 | 3950 | 3760 | 0.9 | 60 | 1490 | 1350 | 1190 | 1760 | |

| 315 | 345 | 3800 | 3625 | 385 | 4750 | 4530 | 480 | 4750 | 4530 | 0.9 | 60 | 1780 | 1560 | 1230 | 1840 | |

| 400 | 420 | 4590 | 4380 | 465 | 5740 | 5470 | 580 | 5740 | 5470 | 0.8 | 61 | 1930 | 1770 | 1280 | 2010 | |

| 500 | 490 | 5530 | 5265 | 545 | 6910 | 6580 | 680 | 6910 | 6580 | 0.8 | 61 | 2360 | 1990 | 1300 | 2100 | |

| 630 | 595 | 6290 | 665 | 7860 | 830 | 7860 | 0.7 | 63 | 2670 | 2200 | 1300 | 2290 | ||||

| 800 | 705 | 7520 | 785 | 9400 | 980 | 9400 | 0.7 | 63 | 2990 | 2220 | 1350 | 2250 | ||||

| 1000 | 830 | 9200 | 920 | 11500 | 1150 | 11500 | 0.7 | 66 | 3280 | 2290 | 1380 | 2280 | ||||

| 1250 | 1005 | 11120 | 1120 | 13900 | 1400 | 13900 | 0.6 | 66 | 3560 | 2250 | 1430 | 2360 | ||||

| 1600 | 1210 | 13280 | 1350 | 16600 | 1690 | 16600 | 0.6 | 68 | 3880 | 2270 | 1600 | 2400 | ||||

| 2000 | 1430 | 15760 | 1590 | 19700 | 1990 | 19700 | 0.5 | 68 | 5120 | 2300 | 2190 | 2650 | ||||

| 2500 | 1700 | 18560 | 1890 | 23200 | 2360 | 23200 | 0.5 | 68 | 6650 | 2530 | 2260 | 2760 | ||||

| 3150 | 2050 | 22080 | 2280 | 27600 | 2810 | 27600 | 0.4 | 70 | 8260 | 2720 | 2290 | 2850 | ||||

| Note: The above data is only for reference when designing and selecting, and the final data is subject to the real thing. | ||||||||||||||||

Recommend Products

Consult

We will offer custom quotes and powerful solutions to meet your needs. Send us your details and we'll get back to you as soon as possible.